|

|

|

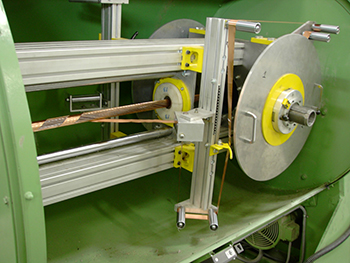

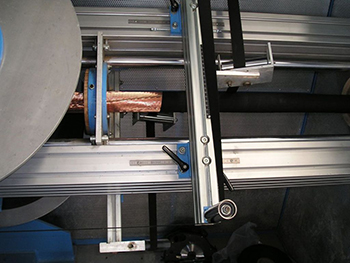

Descriptedtion This line of cable stranding is designed to apply a helicoil layer of copper or aluminum wire over a cable core. The final product produced by this wire stranding machine is mainly a low voltage cable, used to connect a low consumption system by the electric company, where the phase conductor is the aluminum center conductor and the neutral conductor is the cable layer. The final product can also be a medium voltage cable and the copper cables are the shielding of the cable.

Electric Control System The synchronous control system for the separate motorized wire stranding machine consists of PLC and touch screen. It is easy to operate by configuring all the parameters on the touch screen. All the parameters of the process can be collected. The unique data and program collection system ensures that the cable stranding line works in a stable and reliable manner. The accuracy of the length of placement is less than 3% in case of emergency stop and less than 2% when the line stop is normal (PROFIBUS communication control).

Main Technical Data

Cable diameter range | twentymm~ fifteen0 mm |

Thickness of the tape | 0.15mm~ 0.4 mm |

Maximum width of the tape | 50mm |

Dimension of the cushion | Non-metallic tape Φ600mm/Φ800mm |

Overlay of the tape | 0-50% |

Rotational speed | 500rpm |

Stroke of the stranding | 9-160mm |

Stress of stranding | 2.5-15daN |

Motor | 7.5kW |

Main Team

Cancel | 1 set |

Device section by section | 1 set |

Stranding machine | 2 sets |

Meter meter | 1 set |

Tape caterpillar | 1set |

Start | 1set |

Electric control system | 1set |

The synchronous control system for the separate motorized wire stranding machine consists of PLC and touch screen. It is easy to operate by configuring all the parameters on the touch screen. All the parameters of the process can be collected. The unique data and program collection system ensures that the cable stranding line works in a stable and reliable manner. The accuracy of the length of placement is less than 3% in case of emergency stop and less than 2% when the line stop is normal (PROFIBUS communication control).

|

20mm ~ 150mm

|

|

Thickness of the tape

|

0.15mm ~ 0.4mm

|

|

Maximum width of the tape

|

50mm

|

|

Dimension of the cushion

|

Non-metallic tape Φ600mm / Φ800mm

|

|

Overlay of the tape

|

0-50%

|

|

Rotational speed

|

500rpm

|

|

Stroke of the stranding

|

9-160mm

|

|

Stress of stranding

|

2.5-15daN

|

|

Motor

|

7.5kW |

|

1 set

|

|

Device section by section

|

1 set

|

|

Stranding machine

|

2 sets

|

|

Meter meter

|

1 set

|

|

Tape caterpillar

|

1set

|

|

Start

|

1set

|

|

Electric control system

|

1set |