|

|

|

Error 413 (Request Entity Too Large)!!1

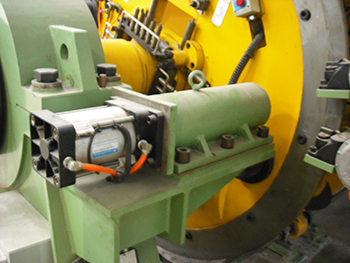

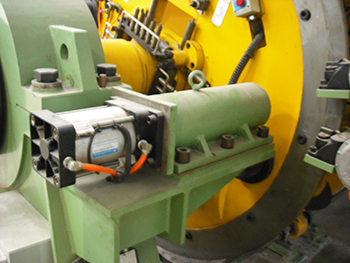

1. Great rigidity

The cage and its flange are made of 25mm and 45mm steel sheet respectively, and enjoy a stable structure. They are tempered and polished with sandblasting to eliminate stress and machined completely by CNC for greater strength. The design of the structure and the machining of the cage make it suitable for working at a high rotation speed.

2. High rotational speed of the cage

|

Diameter of a single braided cable

|

AL: Φ1.5-Φ5.0mm

|

|

Cage speed (full / empty bobbin)

|

Cage 12 190/205

|

|

|

Cage 18 170/205

|

|

|

Cage 24 150/205

|

|

|

Cage 30 120/205

|

|

Established braid length

|

Continuous adjustment of 45-1100mm

|

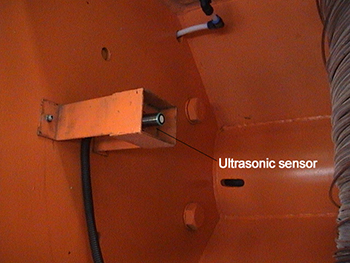

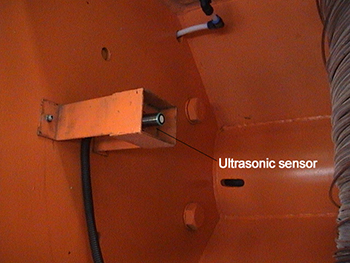

Ultrasonic sensor

Ultrasonic sensor

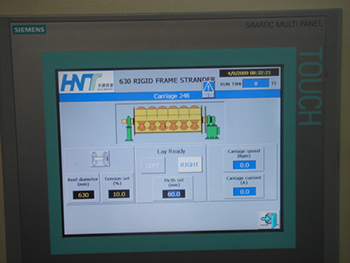

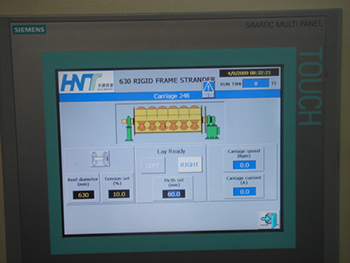

Electric control system

The synchronous control system for the separate motorized braider is different from other similar systems from other manufacturers. It is easy to operate by configuring all the parameters on the touch screen. The unique program and the data collection system ensure that the machine operates in a stable and reliable manner. The accuracy of the placement length is less than 3% when the emergency stops and less than 1% when the production line stops (PROFIBUS communication control).

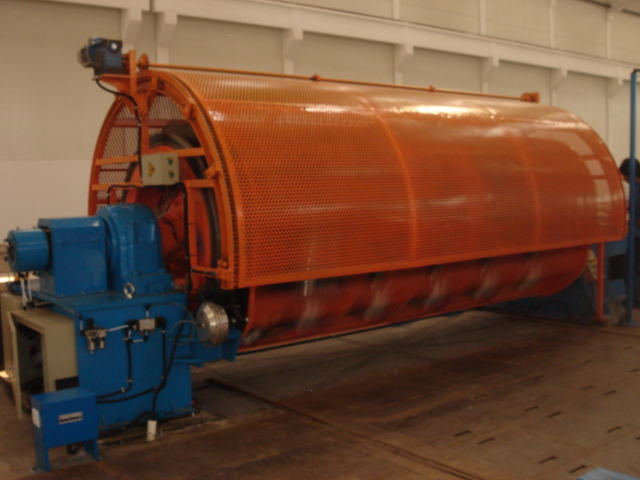

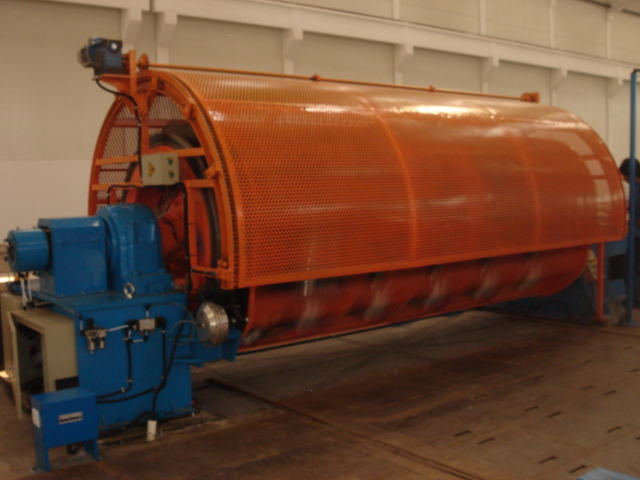

Application

Our rigid frame wiring is specially designed to manufacture copper and aluminum conductors, as well as ACSR at high speed and an excellent conductor surface for high voltage cables produced in continuous vulcanization.

Main Technical Data

|

Number of drums in the cage

|

6.12, 18, 24, 30

|

|

Diameter of a single cable

|

Copper 1.5-4.5mm

|

|

Aluminum 1.8-5.0mm

|

|

|

Aluminum alloy 1.5-4.5mm

|

|

|

Rotational speed of the cage

|

6 coils 200rpm

12 coils 180rpm |

|

18 coils 160rpm

24 coils 140rpm |

|

|

30 coils 120rpm

|

|

|

Established length

|

6 coils 37-500mm

12 coils 44-590mm |

|

18 coils 52-694mm

|

|

|

24 coils 61-819mm

|

|

|

30 coils 72-1100mm

|

|

|

Line speed

|

6.9 ~ 53m / min

|

|

Sizes of the coils in the cage

|

PND 630

|

|

Center height

|

1100mm

|

|

Winch

|

φ2000 (2500) double extraction winch |